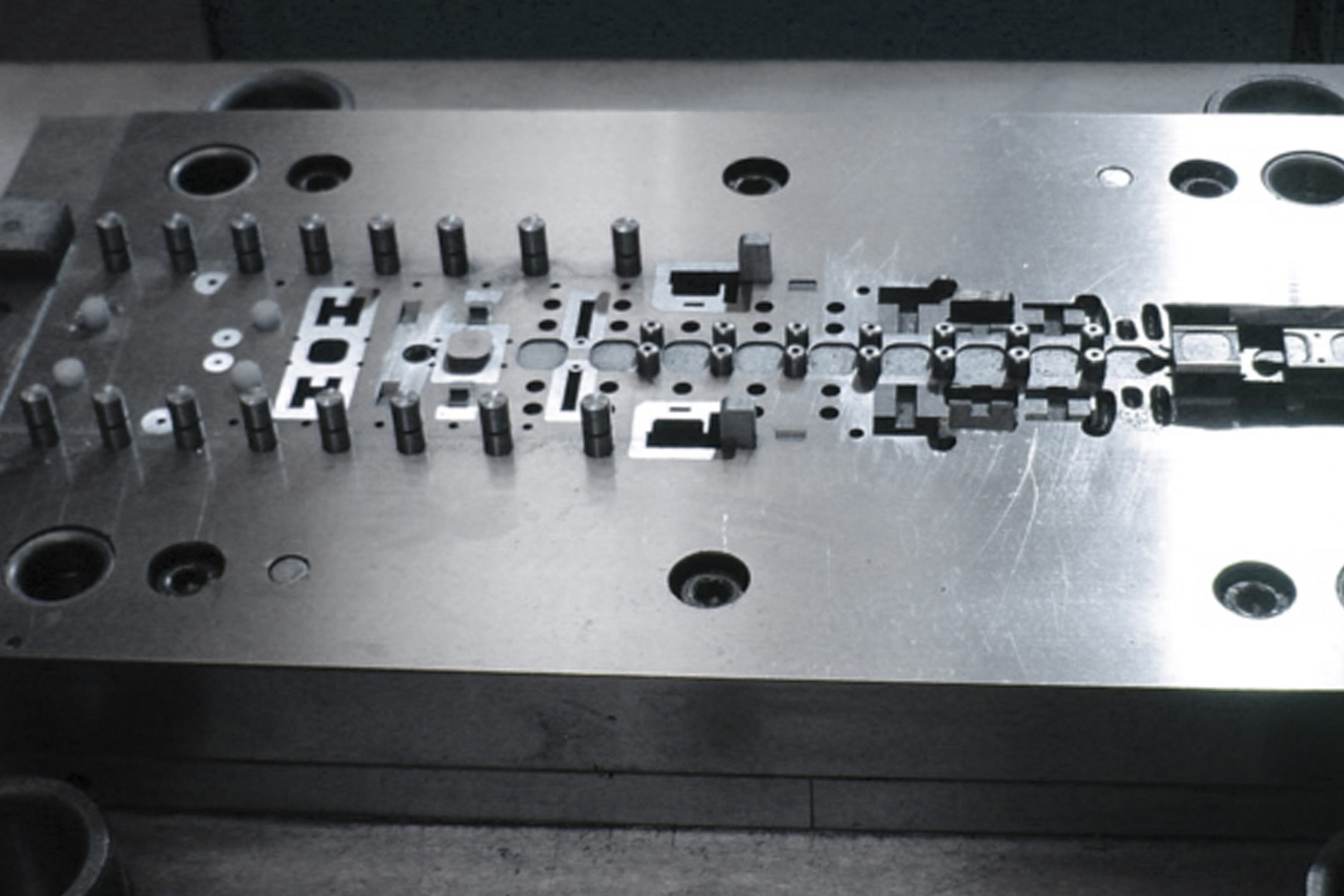

PROGRESSIVE DIE MANUFACTURING, CNC MACHINING AND COLD CUTTING PARTS

Progressive Dies and Tooling for medium and large cold cutting runs.

Tram Solucions excels in the creation, design and manufacture of progressive dies using the most suitable materials to fulfill the strength, resistance, and durability needs of our clients. We provide our clients with solutions to enhance their industrial production capacity by proposing designs and materials. We have a strict commitment to accuracy, meeting the requirements for vertical tolerances of 2.5 μm in 100 mm of height.

- With our years of experience in manufacturing parts, we can guarantee that the progressive dies we manufacture are functioning properly and have been verified. Our clients can rest assured that our progressive dies are made to meet the highest standards of precision and productivity, and are prepared to produce long series of cold-cut parts.

-

The most advanced technology of Wire Machines for progressive dies and tooling manufacturing. We have an impressive capacity of 4,000 hours of monthly operation in our wire machine park. This enables us to fulfill the cost, timing, and quality demands of our clients and supply them with advanced progressive dies with high technological value at a competitive price.

Cold Metal Cutting

Cold cutting metal parts is an art at Tram Solucions. We manufacture medium and large series of cold-cut metal parts. We work with our own progressive dies and with our clients’ tooling in presses of up to 120 Tons. In the cutting section, our team is highly specialized in achieving maximum productivity and optimal performance of the tooling and dies throughout the part manufacturing process.

-

Our versatility in using metals extends to the use of all types, such as steel, aluminum, bronze, copper, stainless steel, and brass, with sizes ranging from 0.1 mm to 10 mm. This allows us to offer customized solutions for every need.

Complementary Services for part finishes: Our complementary services, such as welding, ensure that our clients receive parts ready for use.

- Finishes with Heat Treatments and Coatings: To ensure maximum quality and durability of the metal parts, we deliver the production with heat treatments and coatings such as painting, anodizing, galvanizing, zinc plating, etc. as requested by our clients.

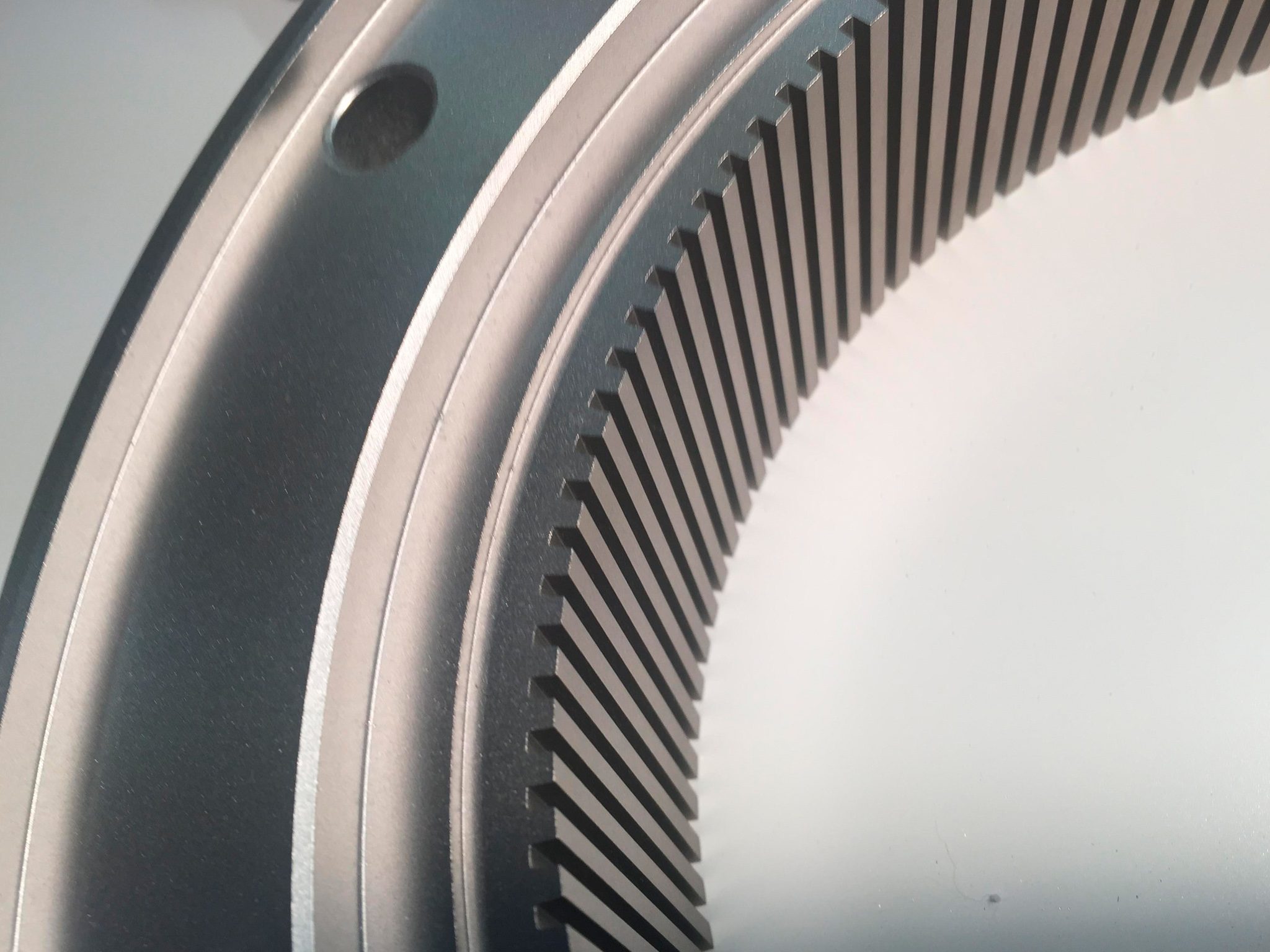

CNC Machining of Parts: quality, speed, and excellence in service

-

The most recent CNC machining equipment. We have 3 machining centers with remarkable travels: X1,100 mm, Y600 mm, and Z600 mm. With these advanced machines, we can offer our clients speed, performance, and an excellent cost-service ratio.

-

Custom Metal Parts. At Tram Solucions, we are prepared to manufacture all types of metal parts according to your specifications. Our focus on customization ensures that we get exactly what you need for your project.

-

Machinery List

MACHINES

FIRST V700 Machining Center / 700x400x500 / 3 axes

KAFO Machining Center / 1100x600x500 / 3 axes

2 MAKINO U6HEAT Wire EDM / 650x450x420 / 5 axes

GER 150-50 Surface Grinder / 1500x600x400 / 3 axes

GUILLEM Press / 120 Tn.

MIOS Press / 105 Tn.

MIOS Press / 75 Tn.

PRESSIX Press / 63 Tn.

GUILLEM Press / 40 Tn.

CONVENTIONAL TOOLS

Hydraulic Block Radial Drills

Pneumatic Tapping Machine

Multiple Head Tapping Machine

Aluminum Automatic Saw MG GAA-350-90

BELFLEX Band Saw

Automatic Blasting Machine with 5 guns

Committed to Excellence: Our R&D Department

Idea Conceptualization

We study with our clients the aspects of the project and its feasibility under the most competitive conditions.

Prototyping

We generate physical prototypes in our machining centers and virtual prototypes in 3D CAD, allowing us to carry out preliminary tests before industrialization.

Design and Development

We propose and provide technological solutions to the design and development of our clients’ products.

Production and Series

Discover our Catalog

Want to know more about us?

Discover a summary of our services and projects.